With nearby firms confronting expanded worldwide rivalry many face expanded weights to lower creation costs. In the nick of time manufacturing has demonstrated mainstream as it focuses on the disposal of waste in its broadest sense. Makers endeavor to lower stock levels and item deserts.

Conventional tooling while at the same time introducing economies of scale regarding part cost frequently demonstrates exorbitant for high worth low volume item producers as they are compelled to hold huge amounts of stock for low worth segments. For makers associated with the creation of new structures the recognizable proof of creation mistakes can likewise demonstrate exorbitant once tooling has started, and introductory stock levels got for creation segments. Acclimations to the plan may prompt squandered stock alongside the extra expenses related with setting up another apparatus for the tooling procedure.

With an end goal to maintain a strategic distance from these possibly expensive creation entanglements various makers have gone to vacuum casting, allowing them source low volumes of creation segments

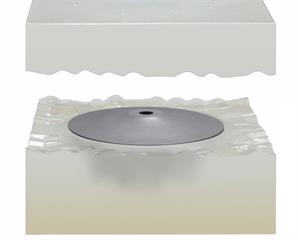

The silicone vacuum casting Process is utilized to make plastic or elastic segments for silicone Moulds. Parts created utilizing this procedure are exact, dimensionally precise copies of the ace example with all profiles and surfaces dependably recreated. The procedure includes the following advances

- A ace example is made utilizing 3D CAD information and any of the accessible Rapid Prototyping forms, commonly SLA because of the great part finish that can be accomplished utilizing this procedure. After creation completing is then done to accomplish the necessary part finish.

- A casting door is fitted to the ace example which is then positioned upon the splitting line and suspended in a shape casting outline. Silicone elastic is blended, de-circulated air through and afterward filled the form casting outline, where it will flow around the ace example.

- The form is then restored inside a warming chamber. When set the silicone shape is cut along the splitting line and the ace example expelled.

- Urethane gum is then estimated, and where shading has been indicated a color included. A casting channel is set and the form is fixed shut.

- The pitch is then blended and poured under vacuum by PC controlled hardware, to keep away from any air pockets or voids.

- Once the tar is thrown, the shape is then moved to the warming chamber where it will stay for around two to four hours, allowing the urethane pitch to fix. In the wake of solidifying the casting is expelled from the form.

- The door and risers are expelled and any after creation painting or plating finished to deliver and precise of the ace example. Each form can be utilized to create between 15-30 castings.

Utilizing a nearby Rapid Prototyping authority, Brandon Medical had the option to source practical excellent creation parts inside days, killing costly tooling costs and the need to hold huge volumes of stock.